The semi-automatic or automatic arc welding process is known as flux-cored arc welding. It is extremely suitable for outdoor welding or windy conditions. It is quite similar to MIG welding, and even some of the same equipment can use, but the filler wire is additional in flux core welding as it is hollow out and filled with flux. Previously shielding gas was used to protect the weld; however, in flux core welding, the flux itself is used to shield the weld pool and coat the entire weld.

In Hurry? Checkout Our Top Pick Of Best Flux Core Welder.

It also lets the weld cool slowly and creates a more stable weld. It is generally used for pipeline welding, general repairs, shipbuilding, manufacturing, and underwater welding. It is much quicker and is consider a mobile process because it doesn’t require carrying a shielding gas. It is also very versatile as it can be both automatic and semi-automatic. These are great opportunities for hobbyists, novice welders, and enthusiasts as it provides secure usage options for any new learner.

A Quick Comparison Of Best Flux Core Welders Of 2020

| Rank | Product Name | Score |

|---|---|---|

|

1

|

Goplus MIG 130 Welder Flux Core Wire

|

9. 7

|

|

2

|

Forney Easy Weld

|

9. 5

|

|

3

|

Super Deal PRO Commercial Flux Core Wire Welder

|

9. 1

|

|

4

|

Vivohome Portable Flux Core Welder Machine

|

8. 8

|

|

5

|

Etosha No Gas 140 MIG Flux Core Wire Gasless Welder

|

8. 6

|

|

6

|

25 Amp 120 Volt/20 Amp Flux Core Wire Welder

|

8. 2

|

|

7

|

Weldpro Flux Wire Welder

|

8. 0

|

1. Forney Easy Weld

Features

- It is made up of metal.

- The power source is corded electric.

- The cord length is 6 feet.

- The metric measurement system is used.

- It comes with a ground clamp and a MIG gun.

The Forney Easy Weld 299 125 FC Flux Core Welder is a Gasless flux core that welds 24 gauge up to 1/4 inch. It accepts two and 10-pound spools, and this is the perfect machine for beginners and novice welders as it has six months warranty along with the capability to mend and weld anything you want. Batteries are not required, and electricity can be directly utilized to use this device. The extraordinarily long cord also is a very convenient feature.

PROS

- No batteries are required or included.

- A warranty of 6 months is available against manufacturer defects.

- The built-in flux provides shielding over the molten weld puddle as it is built into the wire.

- It does not require shielding gas as other typical MIG machines do.

CONS

- Easily gets damaged in high power.

2. Goplus MIG 130 Welder Flux Core Wire

Features

- It has a stainless-steel body.

- It comes with two air vents to optimize the temperature.

- The welding torch is equipped with safety controls.

- It also provides a welding mask and wire.

- It is excellent for DIY and general repair work.

The Goplus MIG 130 smart welder is made of heavy-duty stainless steel which lets it serve you for a very long time. Its portable design, along with a carrying handle allows you to carry it with you tucked in your car and has a wide range of household and backyard applications. Even though it is a household welder, it provides professional quality of fit and finishes. Additionally, it is a no gas welder which uses flux-cored wiring.

PROS

- It offers four levels of current flow settings along with wire feeding speed adjust.

- It has a nifty storage space hidden at the top.

- It can also weld 1-inch thick square tubing.

- It has a very long life span.

CONS

- The electrical breaker starts tripping at times.

3. Super Deal PRO Commercial Flux Core Wire Welder

Features

- It has an extremely intuitive digital soft key control panel.

- It has a copper tip at the end of the gun.

- It comes with a cooling fan which acts as a thermal overload protector.

- It provides four levels of current flow settings.

The Super Deal MIG130 Welder is one of the best household welders available on the market. It is light and is it made of high-quality PVC material. This one uses a convenient flux-cored wire which self-releases meta; inert gases to prevent oxidation. It is designed to be easy to operate for beginners and exudes ease of use and confidence. Weighing a paltry 38 pounds, this welder is small but is also immensely powerful and intuitive.

PROS

- It is probably one of the most portable household welders available.

- It has a range of wire feed speeds.

- It comes with an active temperature control system.

- It has a waveform control technology with an adjustable inductor.

CONS

- It does not offer a steady burn.

4. Vivohome Portable Flux Core Welder Machine

Features

- It comes with Oxidation Resistance technology.

- It has numerous welding speeds from 1 to 10 for different types of metals.

- Its flux-cored wire releases inert gases while welding.

- It comes with a free high-quality welding helmet to protect your face and eyes.

The Vivohome Portable Flux Core Wire No Gas MIG 130 Welder has a flux-cored wire that helps it self-release inert metal gases while welding. It prevents oxidation of the welded parts. It also comes equipped with an adjustable welding speed which lets you control the welding speed according to the metal you are tackling, be it thin steel or aluminium sheet metal or even thicker steel. This welder is designed to be heat resistant and ensures that it does not melt or warp during high heat welding.

PROS

- It is incredibly convenient to use.

- It has an active heat resistant technology.

- It has a handy built-in storage space at the top.

- It provides a wire brush to remove debris and metal particles.

CONS

- The wire that comes along with is not of the best quality.

5. Etosha No Gas 140 MIG Flux Core Wire Gasless Welder

Features

- It has a Synergic Adjustment Function which eliminates the need to match the voltage with the feeder speed manually.

- It uses a 0.8mm or a 1mm flux core wire.

- It offers up to 140Amp output.

- It rectifies the AC input current and changes it to a Direct Current.

- It uses a high power IGBT to invert DC to High-frequency AC.

The Etosha No Gas 140 MIG 140-amp Flux-core Wire Gasless Automatic Feed Welder is a heavy-duty stainless-steel welding machine with an electric choke control. IT offers less splattering, deep penetration and holds somewhat certain formations. Weighing at just under 15 pounds, it is a delight to use. It also comes with a host of safety features that make sure that even beginners can use it for their backyard and household welding needs.

PROS

- It is excellent for metal fabrication and maintenance work.

- It has Automatic Thermal Safety Protection and Overload Safety Protection systems

CONS

- It needs to run on high to weld properly.

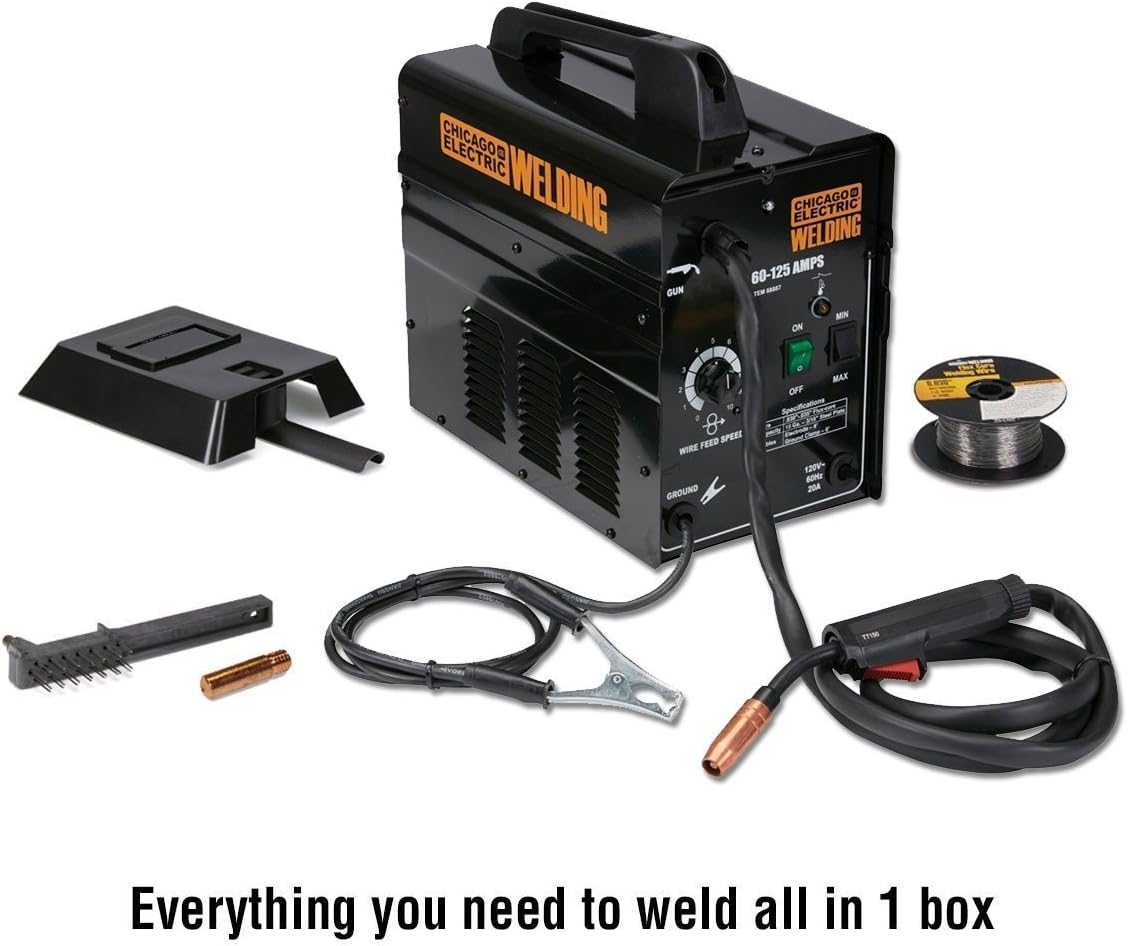

6. 25 Amp 120 Volt/20 Amp Flux Core Wire Welder

Features

- It is exceptionally compact and lightweight.

- It can weld mild steel from 18 gauge till 3/16 inches thick.

- It is ideal for household or backyard welding.

- It can be easily carried around in your car.

- It does not require any batteries.

The Flux 125 welder is one of the most versatile household welders on sale right now. It is a flux core arc welder which is explicitly designed for beginners and uses self- shield/ding flux-cored welding wire. It does not need any external shielding gas usually needed by regular MIG welders. It also comes with variable speed controls and thermal controls to ensure that you can weld your metal precisely as you want without any hassle.

PROS

- The Item is rather lightweight and small

- It is best for gasless flux-cored welding.

- It has thermal overload protection.

- It comes equipped with variable speed wire controls.

CONS

- The speed needs to be turned to the maximum to get a decent weld.

7. Weldpro Flux Wire Welder

Features

- It comes equipped with overheat protection that prevents the welder from heating too much.

- It can be used both outdoors and indoors without the risk of losing shielding gas to the wind.

- It has a working voltage of 115V household voltage.

The Weldpro 90 AMP Flux Wire Welder is a very convenient portable welding unit. It uses Alternate current that varies from 30 to 90 Amps. It is ideal for auto body panel work and can weld through stainless steel and carbon steel with ease. It does not require any additional outlet wiring and can be used with the standard .20-amp household circuit wiring. It uses a power frequency transformer that limits power jumps and trips.

PROS

- It lets you dial the perfect heat range and wire feed speed for the metal of your choice.

- It is long-lasting.

- It can run off the standard household current.

CONS

- It offers a low amperage of only 90A.

Buying Guide For Best Flux Core Welder

The buying guide is essentially a set of instructions and suggestions designed to simplify a purchasing process by providing every necessary and required information mainly to inspire, attract, and inform the readers to make a good purchase and become as close as they can to a rational consumer.

Size Of Flux Core Welder

The size of the device or welder is a significant factor because accessibility and usage directly depend on that. Generally, the designs of the welders are all compact, but very different from one another. It is essential to check the measurements of your shop space or garage before buying the welder because the dimensions need to be matched to fit in the device. Also, if you are looking for using your welder for outdoor purposes, a large-sized method is hugely inconvenient. However, if you need heavy, durable and rough use welders, the more significant the size, the better. Thus, the size depends on factors like cost, design, requirement, and convenience.

Single or multi-purpose usage.

Depending upon what you want to weld and what kind of a finish you are looking for, you should buy a single or a multi-purpose welder. Flux core welders which are multi-purpose (MIG machines) can be used for both gas and gasless operations. Now, if you do not wish to use gas, then a single purpose flux core welder will work. However, welding operations that use gas produce cleaner welds. Therefore multi-purpose machines are better.

Brand

Welding machines are rather new, having been launched in the early 20th century. Few companies have constructed designs since inception. Companies that have helped America design the planes, tanks, and land vehicles of World war II are still active and manufacturing welders. In contrast, some others are merely new players in the business. Both kinds of companies make good quality welders; thus, one has to choose according to the demand’s requirements and other factors. There are popular brands known for their welders which might be a bit costly, but it is a guarantee of quality.

Type of metal

The type of metal you are welding is an essential factor to consider before buying a welder. Not all welders are suitable for all kinds of metal. Flux core welders cannot be used to weld aluminium. Steel can be welded using flux core welders that have an AC output. But to fuse stainless steel, you will need one with a DC output.

Reviews and Ratings

Reviews and ratings by previous customers are very important for research. These are extensively helpful because they tell you how the other customers felt, the things they bought, the choices made, and the results they got. It also helps to shape a proper idea about any object, in this case, a welder. The reviews tell you about features of drawbacks the company will never bring forward. Not just the manufacturing unit, but the reports also deal with customer care services, the delivery unit, and the seller. All of these help a buyer to make a decision and choose a product that suits him or her the best. The ratings also give us the judgment of the products and bring forward the most wanted and the best product among all. The more the number of buyers along with a higher rating, the better the product is. Thus, reviews and ratings together can make a fantastic buying experience that is knowledgeable, aware, and to our best interest.

Quality of lead

The quality of lead will determine what kind of welding you will get done. Torch lead 10 inches to 24 inches is better and is far more durable than 10 inches to 12 inches ground lead. It improves the quality of welding, significantly. Sometimes, stock lead is long and not exactly of this size. However, that does not matter. The longer it is, the more space there is to weld around it. This is better because you will not have to pull the welder close and instead you can move around to produce a clean weld.

Cost

The cost is an essential factor while buying flux core welders. It is a kind of a device which requires technologies, and thus, is available in a vast range of price. One must keep in mind his or her budget, capability, requirements, necessity, type of use, and other factors while purchasing a welder. Cost anyway is one of the chief concerns because you cannot buy something without the money.

Ventilation

Whether it is a home shop or a garage, ventilation is a necessity. It can be open Windows, fan, high ceilings, ventilating fans, open door, but ventilation is a must for a healthy environment. Flux core welding machines especially require more than healthy average air circulation because of its chemical reaction and less of shielding gas as they create Spark and smoke that can be very unhealthy, disastrous, and accident-prone once you have chosen your required welder to consider upgrading or at least modifying the ventilation of your home or garage.

Wire and Reel diameter

Before buying a flux core welder, you should check the diameter of the wire and the reel. Usually, a 0.03-inch diameter wire is used along with a 6 inches reel. However, it is better to have a welder for an 8 inches reel as these reels last longer.

Buying Method

There is a lot that depends on the buying method of your flux core welder. Online shops and websites offer fantastic discounts on various products and also deliver them at home for free. But the whole point of touching and examining an object physically before buying it is removed, and you can never be sure what you are delivered. Often the transportation and delivery also result in damage to the goods and the absence of proper customer care services; the process might be rather lengthy. On the other side, offline shops offer guaranteed quality and nondamaged products as you check them yourself. However, the discount, the option of home delivery, etc. are often not available. Thus, depending on these, one needs to finalize which mode he or she is comfortable with and choose wisely.

Frequently Asked Question

What is flux core welding suitable for?

Being able to offer greater penetration makes Flux-core welding a popular choice as it aligns well with thicker joints. As the welder travels in every direction while holding the torch in several courses, it’s ideal for shipbuilding, general repairs and different types of manufacturing industries.

How thick can you weld with flux core?

035″ Inner shield NR-211-MP will generally allow you to weld steel up to ¼ “thick. Note that this is more than double the thickness maximum of 12 gauge with MIG on 115 volts.

Are Flux core and MIG the same?

Self-shielded Flux core and MIG are different because the flux core does not need any external shielding gas like carbon dioxide or argon and can protect the weld pool nevertheless. The flux core compound contains the welding arc to form a gas to protect the weld pool.

Which is better, Flux core or MIG?

The argument has some merit, and to some extent, flux core welding does need more clean-up of slag and spatter. Dual Shielded flux core welding is even better than MIG welding for light weld coverage after welding and low sprinkle – of course with the correct settings and gas used.

Is welding flux toxic?

Gasless welders like flux core ones are toxic, but they can be extracted at the source because they don’t really “shield” the weld metal. The metallurgy is such that it absorbs the atmosphere without becoming brittle or porous. In a nutshell, all welding fume is toxic.

What’s stronger MIG or stick?

The 70 in E70s6 bare wire and the 70 in 7018 stick rods are of the same strength. 70,000 psi tensile strength is as durable or more reliable than most steels you will weld. For downhill welding on 3/16 and thicker, a 6011-stick rod will penetrate much more profound than bare wire.

Related Posts